SAFRAN has invested 50 million euros in this new Research Center, which spans 10,000 square meters. It will ultimately be staffed by 150 recognized specialists in composite materials, including technicians, engineers and doctoral scientists, who will deploy state-of-the-art machinery and equipment for all phases in the development cycle, from research to prototyping.

Organic matrix composites are becoming more strategic than ever for Safran with the development of the new LEAP engine, successor to the best-selling CFM56. Featuring fan blades and cases made using a proprietary 3D woven composite process, LEAP engines will power new-generation single-aisle commercial jets from both Airbus and Boeing starting in 2016.

This dedicated new research center will enable Safran to continue to extend the scope of application and performance of composite  materials. Combining light weight with high strength and temperature resistance, advanced composites will help meet the pressing challenge of producing aircraft with reduced fuel consumption and CO2 emissions.

materials. Combining light weight with high strength and temperature resistance, advanced composites will help meet the pressing challenge of producing aircraft with reduced fuel consumption and CO2 emissions.

The new Safran Composites research & technology center will play a triple role in addressing these goals by continuing work already under way on innovative composite technologies, such as 3D weaving; exploring new research paths, including higher temperature-resistant resins, within the scope of research partnerships bringing together academia, research labs, specialized small businesses, etc. thus facilitating the circulation of these technologies across all Safran companies.

In general, Safran Composites activities range from material analysis, in conjunction with the corporate Materials & Processes division, to production of full-scale pre-production prototypes. Research staff are investigating new domains, calling on partnerships with academia, other research labs and industry. A veritable cauldron of innovative technologies, the research center fosters the circulation of composite materials expertise across Safran, by giving specialists from different Safran Group companies the opportunity to work at a central hub.

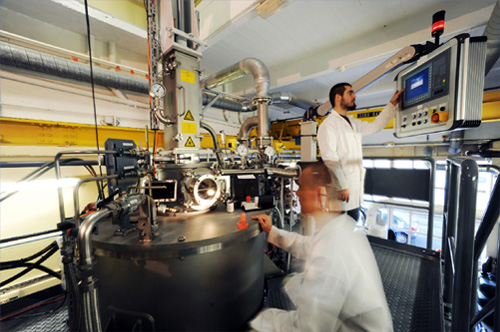

new metallic alloys with exceptional properties. Thanks to this research equipment, the ONERA now masters all the steps of the alloys’ design process. It aims at assisting the manufacturers who work for aeronautics, space industry, energy, car industry and medical industry, who are developing powder metallurgy, and who are committed to eventually producing parts from additive manufacturing, flash sintering or injection moulding.

new metallic alloys with exceptional properties. Thanks to this research equipment, the ONERA now masters all the steps of the alloys’ design process. It aims at assisting the manufacturers who work for aeronautics, space industry, energy, car industry and medical industry, who are developing powder metallurgy, and who are committed to eventually producing parts from additive manufacturing, flash sintering or injection moulding.